The Jewish holiday of Shavuot, with its popular custom to consume dairy dishes, has become linked with marketing the local dairy industry in Israel, reflected in the packing of supermarket shelves with special offers and festive launches. However, local products that seek to challenge the industry will soon land in Israel’s supermarkets: dairy products without the use of animals. These include the products of Remilk, a startup that was established in 2019 and last April received its first approval from the Ministry of Health to market its products to consumers.

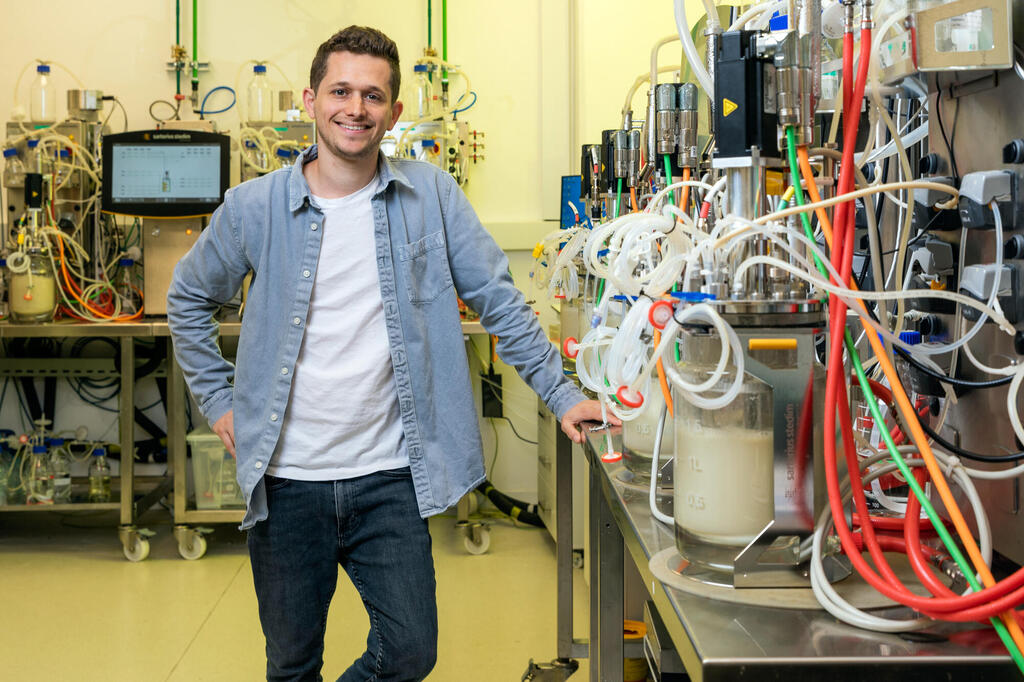

The founder, Aviv Wolff, is responsible for developing cow’s milk protein in the laboratory without the use of animals. The initial products that will be released to the public will be part of a partnership between Remilk and Tara, Israel’s leading privately owned manufacturer of dairy products, and in the coming years the protein will be sold as a raw material to manufacturers in Israel and around the world.

So what does Remilk have to offer the crowded market shelves of milk, cheese and yogurt? The process Remilk uses is called fermentation. The company copies the segment of DNA required to produce cow’s milk proteins, inserts it into yeast and thus turns it into a “factory” that produces the same protein found in animals. Remilk will then market this protein powder to various factories.

“We produce milk protein that is 100% identical to cow’s protein. The cow has a ‘recipe’ and preparation instructions for all the components it needs in milk. We copy this recipe in the laboratory and put it into an efficient microorganism (yeast) that rapidly grows only what we need: a functional substance that becomes a building block of various dairy products only without lactose, cholesterol, growth hormones and antibiotics, and without harming the environment and animals.”

The raw material will be delivered directly by Remilk to factories that currently produce dairy products. Israel, as mentioned, will be the first to use them. “The launch of products involves vigorous work. The common vision is to present the consumer with a wide variety of products, not just one product. Our process is a scalable, proven, industrial production at a competitive price for the dairy industry. We are not stuck in a fantasy of selling a substitute that costs hundreds of shekels.”

Remilk is the first company engaged in fermentation to receive regulatory approval in Israel. “The industry thought that the Ministry of Health’s approval process would take more time,” says Wolff. “This is a new food, not another plant-based substitute with unique processing. There are processes similar to this in the food industry, but the Ministry of Health’s claim is that the percentage of use of the protein in the final product is high compared to the products on the market, and therefore it requires approval as a new food. Our claim was that the relative portion is not really a factor because it’s the same protein, exactly the protein you consume in dairy products. Today almost 90% of all cheeses have an enzyme that is produced by microbial fermentation in a process of genetic engineering. It’s clear that this is a healthy and safe food. Our protein is a known protein that has been consumed by humans for thousands of years.”

Source : Calcalistech MAy 26th 2023