With approximately over 90-million-dairy-farmers, the Indian dairy market stood at a value of Rs 11,357 billion in 2020 .It was expected to grow at a CAGR of 4 to 4.5 per cent.

Also, India’s milk production has increased over the years.

An economic survey estimated that in the last six to seven years, India’s milk production capacity has escalated by 35.61 per cent to 198.4 million tonnes in 2019-2020. It is nearly a 6 per cent increase over 2018-19. Meanwhile, dairy and animal husbandry are estimated to contribute 4.2 per cent to India’s GDP.

Dairy farming a profitable venture

Looking at these figures makes it obvious that dairy farming in India is still a profitable venture and can generate a consistent income for businesses; whether they be large undertakings or micro farms.

Take the example of IIT alumnus and Intel’s ex-executive Indukuri, who quit his job and opened Sid’s Farm in 2012. Today, Sid’s Farm, located in Shabad, Telangana, has expanded its operations to include 120 employees . It has achieved an annual revenue of Rs 40 crores. It delivers milk to nearly 10,000 customers every day.

To put it simply, the youngsters of this generation, who are now entering the arena of the dairy business and farming, are changing the way that these industries have been operating up until now. And modern farming tech solutions are playing a key role in the development of these new age Indian farms and dairies.

How technology is changing the dairy industry?

Nowadays, farmers no longer spend hours hand milking each cow one by one, thanks to the advent of the relevant technology, which has drastically changed the functioning of Indian farms and dairies. Over the last few decades, such advancements in technology have allowed dairy farmers to improve the everyday quality of life of their herds as well.

According to the Ministry of Food Processing Industries, the capacity created by private dairies in the last 20 years is more than the capacity set up by the cooperatives in over 30 years. It’s all because of the advanced high-tech setups in private farms. Which indicates that development is proportionate to tech-adoption.

Director at Mr Milkman by Mittal Happy Cows Dairy Farm, Neeraj Mittal says that technology adoption is imperative for them to improve their operations,

Technology adoption

“The use of technology has definitely helped us grow faster. Technology has also reduced our dependency on manual labour and especially during the pandemic, technology has helped in making sure our delivery process has been smooth,” he asserts.

Neeraj Mittal, Director at Mr Milk by Mittal Happy Cows Dairy Farm,

Mittal’s farm in Maharashtra is fully equipped by Swedish tech brand DeLaval, who have planned and installed the technology at the farm for them. While their software partner is Indian dairy-tech startup Mr. Milkman. “Technology has been a great helping hand to the dairy industry and at the Mittal Dairy Farm,” he says as he feels that it was all because of the automated processes in the farm, that they and other farms like them could keep going during the pandemic.

Citing the example of his own farm as it is entirely automated, he tells us about the processes where dairy farms are leveraging technology, “We use an automated milking system through which the milk is directly stored in the milk parlour at a certain temperature and directly packed into milk cartons that are recyclable and eco-friendly. We maintain the delivery process through our software; hence we can assure our customers of the timely delivery of our products. Also, our app is extremely user friendly. Our customers can place their orders and pay directly on the app,” he clarifies.

Hatsun a leader amongst private players

Similarly, a leading private dairy label, Hatsun Agro, which already has 18 processing units, has recently set up a 19th fully automated dairy processing plant in Solapur (Greenfield Dairy) with imported equipment from Germany. According to an official, the plant will process 6 lakh litres of milk per day (LLPD).

Additionally, the setting up of this plant will help onboard dairy farmers to the mainstream network and will boost the income of over 75,000 to 90,000 dairy farmers in Maharashtra.

Having said that, it’s not only the co-operatives, private or large farms that are getting tech-savvy, but small dairy farmers too are now utilizing modern dairy processes.

A small dairy farm owner, M. Sharma who has over 30 cows of a native breed in Greater Noida, says, “The technologies have the potential to change the way we manage cows.”

He has been milking his herd using a herringbone milk parlour, which not only saves time but also saves manpower, money, and allows them to monitor the freshness of the milk. Sharma feels that since its inception, his business has grown significantly, and he is now supplying and delivering unadulterated A2 milk and milk products to at least 50 + customers.

Herd tracking

“I believe that technology is present in all aspects of dairy operations. From feeding to milking to herd tracking. Today’s technological solutions are more advanced, allowing us to better manage our farms and animals. As a result, disease losses are reduced, longevity is increased, and animal well-being is improved,” he adds.

In another instance, Akash Patil, the owner of Motake dairy farm in Maharashtra, uses technology to monitor his cow herd’s health. According to him, using technology-based tags eliminated the need for labour, manual intervention, and guesswork in determining the heat and health status of an individual cow or a group, which has only increased the value of his revenues.

This suggests that technological interventions in dairy operations are not only making their lives easier but also increasing the farmer’s incomes, which is the government’s ultimate goal by 2022.

Technology has opened more avenues

Experts also agree on the fact that it was mainly due to technological interventions that the sector was barely impacted by the pandemic. In fact, it turned the crisis into an opportunity in many ways—there was more SMP production, it aided the formalization of the dairy sector, and the players went online.

According to FAO data, India’s milk output reached 195 million tonnes in 2020, up 2.0 per cent from 2019, underpinned by the continued rise in dairy cattle numbers and improved feed and fodder availability due to favourable monsoon rains (June to September).

When consumption and sales of dairy items were witnessing a dent, the cooperative model and private companies in India went out of their way to protect the milk producers.

They kept procuring milk resulting in surplus supply and channelled it to drying plants for the manufacturing of skimmed milk powder. Which actually is a whole new gamut of technological processes (pasteurizing, heat treatments, drying and more) and can be considered as a different industry within the dairy sector. We can, however, say that the fast mobilisation of the village cooperatives’ network facilitated milk output growth.

SMP stocks

In what seems like a record production of skimmed milk powder, India doubled its production in just one and a half month during the lockdown. The figures of NDDB reveal that on March 15, the stock of milk powder was 70,000 metric tonnes.

On the flip side, due to going online and relying heavily on technology in the dairy business, the unorganised dairy segment was greatly diminished.

“There was a clear and rapid shift in milk collection from the informal to the formal channel at the farm level immediately after the lockdown, with farmers delivering more milk in the organised collection centres of private companies and cooperatives. The informal milk market disappeared almost completely from April to June 2020, and it is attempting to recapture its market share. However, even before COVID-19, there was a movement towards organised milk markets that became more pronounced during the pandemic,”

says Shiva Mudgil, Research Analyst at Rabobank, on the emerging trends in the Indian dairy sector.

Technological interventions during the pandemic

The dairy industry adopted and shifted to various new methods and processes; including major technological interventions, in response to the changing trends thrown up by the pandemic.

To summarise, consumers’ emphasis on quality, safety, and hygiene prompted-farms-to implement-technological solutions to cater to their customers who work-from-home. These changes were implemented from the shop floor to the management level; and included the adoption of online payment, e-commerce, and e-logistics solutions.

Meanwhile, many companies have established new business channels and partnered with retail and online delivery start-ups; such as Bigbasket, Milkbasket, Supr Daily, and others. Dairy companies, in fact, are attempting to increase their engagement with QSR chains; that have highly developed online and take-away business models. Take, for example, Domino’s India.

Farm sustainability

Another emerging trend is that of sustainability, in which stakeholders are working together. Farm owners are now making continuous efforts to implement sustainable processes in their operations; whether it is in chilling the milk, packaging it, or reducing spoilage. This is pushing farms to partner with innovative start-ups.

“Technology will play a crucial role in augmenting sustainability by way of data collection, analysis, and adoption of tools than can leverage the chain’s maximum benefits, starting with the dairy farmers. Stellapps, Promethean Power, and Inficold are some of the companies working on this concept,” states Mudgil in the Rabobank analysis.

Why dairy needs technology?

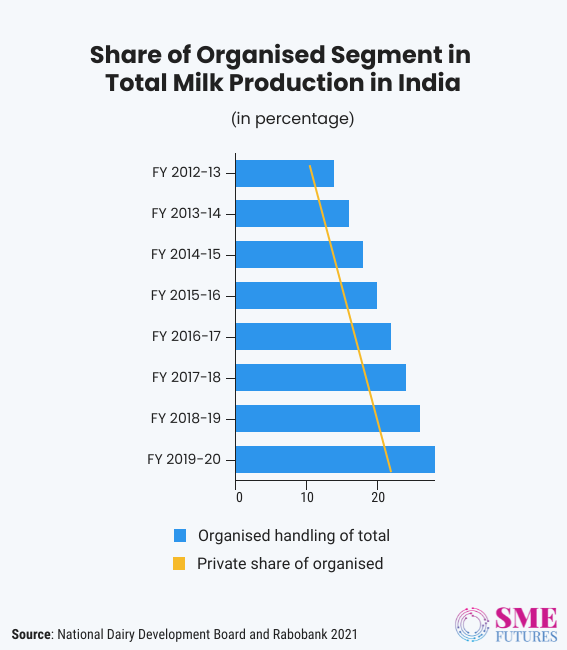

Meanwhile, it’s important to note that unlike in the West, India’s dairy industry is highly unorganised. Which means that about 60 per cent surplus milk is handled by the unorganised sector (milkmen), while the remaining 40 per cent is procured by the organised sector comprising of dairy co-operatives and private companies. In developed countries, about 90 per cent surplus milk is handled through the organised sector.

According to the experts in the field, due to the highly unorganised nature of the sector, technological advancements have been minimal. In fact, a lack of technological adoption has created a slew of other issues for the sector.

Some of these challenges are—high wastage and inconsistent quality and quantity of milk for many small farmers.

According to Chambers of Commerce and Industry of India (Assocham) and MRSS estimates, about 3 per cent of the milk produced gets wasted annually.

Wastage a challenge

The volume of the wastage, coupled with the increased demand for dairy products, may hamper India’s plan to produce about 300 million tonnes of milk by 2024.

In addition, the average milk yield of cows in India is lower than that of their American counterparts—1,248 kgs of milk per cow in a year compared with ~10,000 kgs of milk per year. Indian dairy farmers must increase production and focus on reducing wastage to meet their targets.

“The Indian dairy industry is mainly based on the collection module as farmers are unable to manage a bigger herd. People are now preferring single sourced milk to make sure of its hygiene and quality. With the right kind of technology, small scale dairy platforms can grow their farms and assure customers about the purity of their milk,” says Mittal of Mr. Milk. According to him this will aid the sector in mitigating the wastage of milk.

At the same time, even if India is the largest milk producing nation, because of its large cattle population, it doesn’t have high milk productivity.

Lack of technology in milk production

“One of the bottlenecks hindering the growth of milk productivity is the lack of a technology-based system of production in rural areas,”

opines Pravin Kini, Founder & MD, Tropical Animal Genetics.

According to him, 80 per cent of Indian cattle are owned by farmers with a herd size of up to four animals with little automation and infrastructure. Moreover, the poor genetics of the herd also leads to low milk productivity.

Parallel to this, the appetite and demand for dairy products is on the rise too.

According to the National Dairy Development Board (NDDB), the demand for milk and milk products will surge up to 266.5 million metric tonnes by 2030.

Middle class the decision maker

This is owing to the growing urban population, an expanding middle class with a high disposable income, and consumers seeking out healthy food options. The advent of COVID-19 has also triggered a change in the consumption pattern of dairy products including curd, paneer, ghee and other cheese variants.

However, the supply side is not yet equal to this challenge of fulfilling this ever-growing demand.

According to Kini, the demand-for-milk is growing at 6-percent annually in India but supply is growing at only 4-percent. “To meet the increasing demand for milk and ensure that India is self-dependent about milk production, there needs to be more productivity. Hence there is a need for a second white revolution. The gap between this supply and demand can be addressed by adopting innovative dairy farming practices,” he opines.

Also, most of India’s dairy presence remains in rural areas which lack a continuous and reliable power supply. Here, milk chilling is one of the major hurdles for farmers.

According to experts such as Shridhar Mehta, Director at Prompt Equipments; an Ahmedabad based dairy tech firm, “I fathom that the majority of milk-collection-centres also do not have cooling infrastructure such as chilling centres, cold chains, or bulk milk coolers. Which can be a huge challenge for them. Whereas solutions to instantly chill milk are available, we just need more efforts for their higher adoption.”

But on the other side, it also presents a huge opportunity for the dairy segment, according to Mehta.

Instant chilling at production points

As per the projections of the government’s National-Action-Plan; there is a requirement of 8,80,000 rapid milk chillers in India, and this translates into a $3 billion opportunity.

Another challenge for India is to enhance its export share in the global market.

Currently, India’s exports share in the world is meagre—0.36 per cent.

The goal is to take this share up to 10 per cent. Another aim is to double the processing capacity from 53.5 million metric tonnes (MMT) to 108 MMT by 2025. The government, in its roadmap for 2025 for the dairy sector also aims to increase value added products from 23 per cent to 40 per cent.

India’s export of dairy products to the world was 51,421.85 MT, worth Rs. 1,341.03 crores or US$ 186.71 million during the year 2019-20.

Authenticity of milk is critical

Adulteration is yet another very prominent issue for the milk sector.

Milk is tainted either intentionally or accidently during the production and processing of milk. Milk adulteration is primarily an economic act used to generate extra income. However, the primary reasons for adulteration are the demand and supply gap, the inability to meet urban demand, a lack of milk purchasing capability, the lack of a systematic approach to milk production, and the desire to extend the shelf life of milk.

There have been numerous reports of milk-adulteration in the past and the government is now taking care of such issues.

However, the stakeholders are unanimous in their belief that technology solutions can assist in mitigating all of the dairy-industry’s-challenges. While digitalisation will play a crucial role in making the transformation possible.

Tech interventions are imperative

Digitalisation will have a profound impact on the ‘milk production’ segment in the value chain. In India, dairy farming is unorganised, so technology penetration is relatively less; however, in the last five years, numerous start-ups have mushroomed in this space. These firms aim to increase farmer productivity and reduce wastage.

One of the key areas where digitalisation can have a significant impact is cattle management. Farmers can track cattle feeding patterns and monitor their health by leveraging IoT and advanced analytics. This is likely to boost cattle productivity and milk yield. However, cattle monitoring via AI-based solutions is still in its infancy in India; with only a few companies providing this service.

Prompt Equipments is a pioneer in this field. Over the last 27 years, the company has launched a number of innovative products and solutions ;that ensure transparency and quality in the milk supply chain. Some of their products include, iSmart milk analyser, milk procurement software, a collection system, chilling solutions, Farm365 management apps etc.

Mehta says, “From the cow to the consumer, milk travels a long way. Prompt’s innovative products and solutions cover the entire spectrum from farm management solutions; milk collection systems and milk testing equipment to ensure that the quality and purity-of-the-milk is retained at every step of its journey.”

Last year, they tied up with IIT Mumbai, to invent a wearable belt ‘BovSmart’. The belt utilises AI and the IoT to monitor cattle breeding and send timely alerts to farmers.

IOT solutions

“It’s an animal-wearable, which is a comfortable, non-invasive, IoT-solution designed for the timely-detection of the onset of the cow’s-heat-cycle. Developed with a specialised algorithm, it is designed to give actionable alerts which ensures timely breeding with a high success rate. The software leads to improved farm productivity and better animal health,” says Shridhar Mehta, Director, Prompt.

Mehta further adds, “Our efforts are focused on combining business intelligence and digital innovation to elevate the global standing of the Indian dairy industry. Dairy farmers are the focal point of our innovations, and we are proud of the fact that we have been able to make a difference in the lives of lakhs of farmers over the last 27 years.”

Stellapps Technologies, another dairytech company, digitalizes and enables supply chain traceability for dairy companies. Their solution, mooOn, is similar to Prompt’s in that it helps to maximize cattle productivity and herd management. It is done via a wearable device and app. Through the IoT and sensor based SmartMoo cloud; they have digitised cattle health, milk production, milk procurement, milk testing, and cold chain management.

Moo pay an innovative approach

Stellapps launched MooPay, a direct payment platform for dairy processors and cooperatives, last year. This service makes use of the entire Stellapps product and service portfolio to facilitate instant payment into dairy farmers’ existing bank accounts and assists them in receiving their actual payments without delay. In a recent development, a Stellapps has signed an agreement with India Post Payments Bank (IPPB) to digitise the dairy milk procurement value chain and promote banking facilities at milk collection centres.

Another start-up in the field is Bodhishop, which is trying to solve the problems of adulteration as well as other issues.

Rajas Paranjpe, its founder says, “Everyone speaks about the adulteration of milk; but nobody is interested to know why this adulteration happens. As a start-up, we decided to take up this challenge and jumped in to find out the root-cause-of-adulteration. After thorough research, we identified that the selling price of milk products, traceability and over-dependence-on-technology (lab testing, reports etc.) are a few of the main reasons for adulteration.”

To solve this issue, Bodhishop started a tech+human process of verification in 2018.

Packaging of fresh farm milk

“We started visiting farms periodically, observed the cows, the process of making milk products; packaging and the basic philosophy of the farmer/seller who was selling these products. In addition to requesting periodic lab reports, we came up with strict parameters (no hormone injections, no formalin, etc). That had to be met when it came to any food product. Farmers just have to keep on making the best products without any adulteration,” he continues.

The physical verification of the farm and the process followed is a major service; that Bodhishop as an E-commerce platform provides to its customers. Besides that, Bodhishop also assists sellers or farmers in getting their branded products sold, marketed and shipped across the globe.

Paranjpe tells us, “A few of the major challenges that the farmers approach us with are sales; marketing, branding, packaging and logistics since organic and A2 milk products are expensive. Since such products are free from preservatives and chemicals, they also have a short shelf life. Bodhishop provides 100 per cent support for free warehousing, free marketing, free packaging training and shipping to Gaushalas.”

Warehousing startups

The start-up offers warehousing facilities to farmers at no extra charge. Once they deliver the products to the warehouse, it takes over from there for the final packaging, selling and logistics.

“We work on getting these products safe for transit and the necessary export compliances at no extra charge. This way, the farmers can continue to focus on production while we get them sales through our platform. We have also introduced all our farmers to the latest technology of packaging glass bottles called as Airpack,”.

Currently Bodhishop has 8 gaushalas listed on their website. While they work with 4 more gaushalas for their Export Incubator Programme and Fodder Drive. They have many more plans for the future. “In the coming year, we wish to introduce more indigenous local products from different geographical locations. That will be managed by a separate verification and onboarding team. We are also planning to create-free-training-videos with experts that will teach farmers about how to start organic farming . It will make the highest quality cruelty-free dairy products that are gaining popularity in India and abroad,” he avers.

Development lies in dairy-tech

The dairy sector in India is still unorganised; but dairy farmers are conscious of the implications of digital transformation and the growth through it. Covid-19 has also established a narrative for them.

That is why, the dairy sector holds immense potential to bring the rural economy back on track. High-end technologies can transform the dairy value chain by unlocking access to relevant insights; products and services at the right time to smallholder farmers. Also, quality and traceability solutions can make India an export hub for dairy and data driven decisions; in dairy farming could lead to building a smart dairy value chain.

It’s just that the small farmers, whether rural or urban, require more assistance and guidance to become digital.

“India is still catching up with new technologies. However, there has been tremendous growth through technology in the dairy sector; and with modern technology there is definitely more scope for development in the future,” says Mittal.

Even though the adoption of new technology and digitalisation has been slow in the sector; it is gradually permeating the sector, resulting in its growth. With dairytech start-ups entering the space and bridging the gaps in cattle management and the supply chain; the scenario is changing. The future of the Indian dairy sector appears bright; as digitalization is expected to usher in a new era of growth.

Source : SME Futures July 18 2021, by Anushruti Singh