Last week one piece of news made me think deeply and explore the vast impact of this disruption in the future. The news was about Remilk establishing its world’s largest full-scale precision fermentation facility. This center is established in more than 750,000 square feet in Kalundborg, Denmark . At the new facility, Remilk will produce non-animal dairy protein for use in products like cheese, yogurt, and ice cream; in volumes equivalent to that produced by 50,000 cows each year. Considering 10000 Litres per annum of milk production per cow with 65% of them in milk; this plant will have a capacity to produce 1 millions litres per day equivalent to milk proteins.

We have been hearing a lot about many startups entering into the dairy and meat alternative industry using precision fermentation since the last few years. However most of the experts remained skeptical about scaling up of such lab scale endeavours. I thought of exploring the power of such a facility to disrupt the global dairy sector.

Minimum Global milk demand

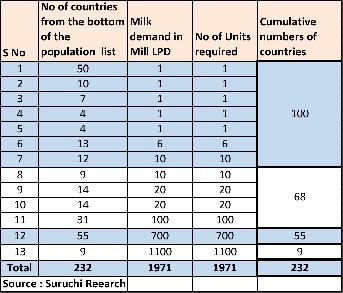

First I looked at the total demand of milk in the world . I applied the 250 ml per capita paradigm by WHO on the population list of 232 countries in the world. I found some very interesting insights which could be seen in the following table. While the top 9 countries requires a minimum of 1.1 Billion litres of milk per day; the bottom 100 countries require 21 million litres of milk. The bottom 50 countries demand 1 million litres of milk per day only.

Doesn’t it look plausible now ? I leave the answers to all the experts around who have been ignoring this intervention and not acknowledging it as a threat to the dairy sector.

Let us understand more about precision fermentation . As per GFI, “Ancient civilizations used microbial cultures to preserve foods, create alcoholic beverages, and improve the nutritional value and bioavailability of foods ranging from kimchi to tempeh. Over the past century, the role of fermentation has expanded far beyond its historical usage to a much broader range of applications.

Fermentation now spans industrial chemistry, biomaterials, therapeutics and medicine, fuels, and advanced food ingredients. The suite of tools developed through fermentation’s evolution is now poised to revolutionize the food sector by accelerating the rise of alternative proteins.

Three types of primary fermentation

1. Traditional fermentation uses intact live microorganisms to modulate and process plant-derived ingredients.

2. Biomass fermentation leverages the fast growth and high protein content of many microorganisms to efficiently produce large quantities of protein.

3. Precision fermentation uses microbial hosts as “cell factories” for producing specific functional ingredients.

These ingredients typically require greater purity than the primary protein ingredients and are incorporated at much lower levels. These functional ingredients can improve sensory characteristics and functional attributes of plant-based products or cultivated meat.

Precision fermentation can produce enzymes, flavoring agents, vitamins, natural pigments, and fats. Examples include Perfect Day’s dairy proteins, Clara Foods’ egg proteins, and Impossible Foods’ heme protein.

Innovations are occurring across all three types of fermentation.

Investment and Technologies

There has been huge investments in precision fermentation projects in the past few years. Protein alternative companies raised $530 million in disclosed investment in 2018. In the space of one year this investment increased more than three-fold to $1.66 billion. Despite a global pandemic and financial uncertainty, confidence in protein alternative start-ups was resilient. Surprisingly investment in both 2020 and 2021 in this sector exceeded $3 billion. Historically, ingredient formulation has been the key focus for investors; with these businesses receiving more capital than any other category of food technology. Ingredient formulation describes the blend of proteins (e.g. soy, wheat and pea) . Alongside other plant-based ingredients to form a final meat or dairy alternative product are also used. Here, development chefs play a significant role in the success of the product.

The trend is becoming a craze in India too.

Humane Society International/India recently concluded their second annual Humane Entrepreneurship Program with a pitch day. Their latest cohort displayed various innovations, right from lab generated tissue for cosmetic testing. Bovine milk made from microbes, plant based meat, plant based paneer, plant based egg to cruelty free men’s fashion accessories. The startups were BioDimension Technology, Phyx44, ProMeat, Naya M!lk, Ethik, and Plantish Foods.

There are three reasons for technologies like precision fermentation to become the first choice of researchers and investors both.

- Animal agriculture contributes greatly to global warming with a 16.5 share of global greenhouse emissions.

- Around one third of the freshwater in the world is used for rearing livestocks and manufacturing animal products.

- In certain areas livestock farming also involves cruelty and poor animal husbandry practices as a third factor.

In India these three factors may not be applicable at the same levels of severity as in the developed world. However we can not deny the benign cruelty on Indian cattle which have been abandoned by the farmers. This reminds me of a famous quote by Margaret Read.

Indian scenario

I can see this small group of bio-engineering-enthusiasts building a better world for the coming generations. I won’t be surprised to relish lab made cheese, paneer, protein shakes, greek yogurts, widely available in Indian-markets by 2025-26.

It is projected that by 2030, 50% of auto sales in India will be of electric vehicles. The disruption in food also is likely to follow the same trajectory.

As per the findings in a report by Rethinkx “By 2030, demand for cow products will have fallen by 70%. Before we reach this point, the U.S. cattle industry will be effectively bankrupt. By 2035, demand for cow products will have shrunk by 80% to 90%. The cost of modern foods and other precision fermentation products will be 50%-80% lower than the animal products they replace; which will translate into substantially lower prices and increased disposable incomes. “

This is the right-time for the experts and think-tank of our country to assess the future-scenarios linked to these disruptions. Underestimating these disruptions today may cost too much tomorrow.

Source : A blog by Kuldeep Sharma , Chief editor Dairynews7x7