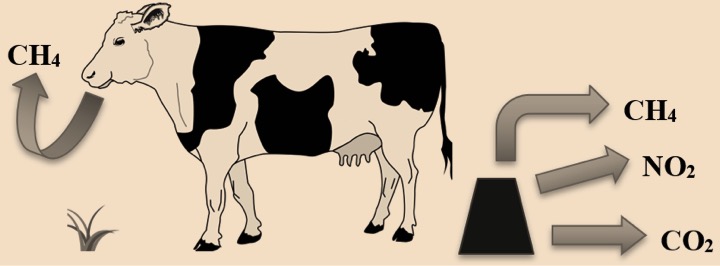

With the increasing focus on climate change and India’s declaration at the Glasgow Summit to cut its emissions to net zero by 2070, there is a clarion call within every industry to create a roadmap for mitigating carbon footprint. A study by FAO has found that 36% of greenhouse gas (GHG) emissions in India originate from its agri-food systems. Further, 14.5% of all human-caused greenhouse gas (GHG) emissions come from livestock supply chains. And scientific studies have indicated that adopting energy efficient technology in animal feeding and manure management could help the global livestock sector cut its emissions of greenhouse gases up to 30%. To address the issue of energy efficiency in livestock management, there is a growing emphasis on deploying technology to convert animal waste into biomethane/biogas and generate wealth and energy from such waste.

Against this backdrop, if we break down the data on livestock’s contribution to greenhouse, then 90% contribution comes from cattle and buffaloes, while the remaining 10% comes from small ruminants. Presently India produces 23% of the world’s milk (200 million tonnes) and the dairying industry employs approximately 100 million people. Hence, there have been several initiatives to find innovative solutions to help dairy farmers better manage and monetize the byproducts of cattle dung. In this context, the National Dairy Development Board has been working closely with dairy cooperatives and women dairy farmers to provide support in the installation of digesters for biogas . Under NDDB’s Manure Management Initiative,biogas plants are installed by the dairy farmers in their backyard for producing gas to be used as cooking fuel. The bio slurry produced from these biogas plants is primarily used by the farmers in their own field and surplus bio slurry gets sold to other farmers or converted into organic fertilisers. It is noteworthy that Mujkuva Sakhi Khad Sahakari Mandli is the country’s first women led Manure Cooperative. The gradual proliferation of biogas plants has led to significant savings on cooking fuel expense. Additionally, the widespread adoption of these models will go a long way towards reducing the health hazards of kitchen smoke, mitigate the adverse impact on environment and provide an additional stream of income for dairy farmers.

Against this backdrop, there are model cooperatives like Banas Dairy which has begun generating 200 cubic metres of raw biogas from dung manure daily. After purification, the dairy cooperative converts the raw biogas to 800 kgs of bio-CNG and sells the CNG at Rs 50 per kg which is lower than the market rate. This bio-CNG is now being used for fuel requirement of milk tankers etc. for Banas Dairy.

The indigenous cattle generate up to about 10-15 kgs of dung per day, and a whole range of waste management practises that are familiar to us have passed down by way of indigenous knowledge – such as the usage of dung for plastering walls and floors in rural houses. Innovations in the management of dung will go a long way towards empowering livestock farmers. To encourage this trend the Department of Animal Husbandry and Dairying had conducted the Animal Husbandry Grand Startup Challenge – an event that put the spotlight on a host of innovations by startups such as usage of cow dung along with bio-based products to create composite materials that can substitute virgin wood, concrete, synthetic wool and plastic products within homes and offices.

To incentivise the adoption of energy efficient technology by dairy cooperatives and private dairies, the Department of Animal Husbandry and Dairying has revised the Dairy Processing and Infrastructure Development Fund’s (DIDF) scheme and Animal Husbandry Infrastructure Development Fund scheme under which dairy cooperatives and private players can avail incentives for installing renewable energy infrastructure in milk processing units. A noteworthy example which needs mentioning is the country’s biggest biogas-based electricity generation plant for the Milk Producers Cooperative Union Plant in Ramnagar (Varanasi) that will utilize about 100 MT of cow dung every day to produce biogas in about 4000 cubic meter/day capacity biogas plant. 194 villages have been identified for supply of cow dung in the vicinity of 10 KM from the Varanasi dairy plant having about 68.6 thousand animals (livestock census) which produce approximately 779 tonnes of dung per day (at an average of about 11 kg). The biogas in this plant will be utilized to produce electrical and thermal energy which will meet the energy needs of the dairy plant. This project will result in net energy savings of about Rs.0.40/litre of milk handled at the plant. Further, in addition to earning an income through the sale of milk, dairy farmers in the vicinity will be able to sell the cattle dung at Rs.1.5 to Rs.2/kg.

As dairy cows generate approximately 10 kg, and buffaloes about 15kg of dung daily – rapid adoption of biogas technology could go a long way towards meeting the country’s energy needs and generating additional income for farmers. More importantly, given that India has the world’s largest livestock population (537 million), adopting best practices in the context of dung management, will help us inch towards our stated goals in the Glasgow Summit by generating additional carbon credits for the country.

Source : Business Standard : May 03 2022, written by Atul Chaturvedi, Secretary, Ministry of Animal Husbandry and Dairying